How is digestate a winning solution for your fertilization strategy?

The by-product of the biomethanation of livestock effluent (digestate) offers added value to animal waste while reducing the environmental impact of the management of slurry and manure from the farm.

The treatment of slurry by biomethanation allows the reduction of the organic load and pathogens, partly responsible for the contamination of surface water and groundwater. The greater fluidity of the treated slurry promotes its infiltration into the soil during its spreading, thus reducing the risk of fertilizer runoff, particularly phosphorus and nitrogen.

Although the total fertilizer load is not modified by the process, the bioavailability of nutrients is improved, which increases their efficiency coefficient in the field and further reduces the total quantity of fertilizers to be applied to the crops.

The use of the by-product resulting from the biomethanation of livestock effluent (digestate) not only has agronomic advantages, but also considerable economic and environmental advantages!

Agronomical advantages

According to different studies, the digestate will have a positive impact on:

Physical and chemical characteristics of whole slurry and slurry treated by anaerobic digestion.

1A lower C/N ratio indicates that the carbon was used by the anaerobic bacteria to make CH4 in the digester, and the N2O formed will be converted into ammonia form (NH4+) and becomes highly assimilable by the plant and less volatilized in the digester. environment in N2O.

Economical advantage

The digestate makes it possible to increase the forage yield (t/ha) compared to whole slurry. It also provides as good performance as mineral fertilizers over 3-year corn-triticale rotations (Pastorelli et al. 2021). This situation can become an advantageous solution, since it is a product derived from biomethanized livestock effluent, but without gas which would in any case be evaporated into the environment following spreading in the field. .

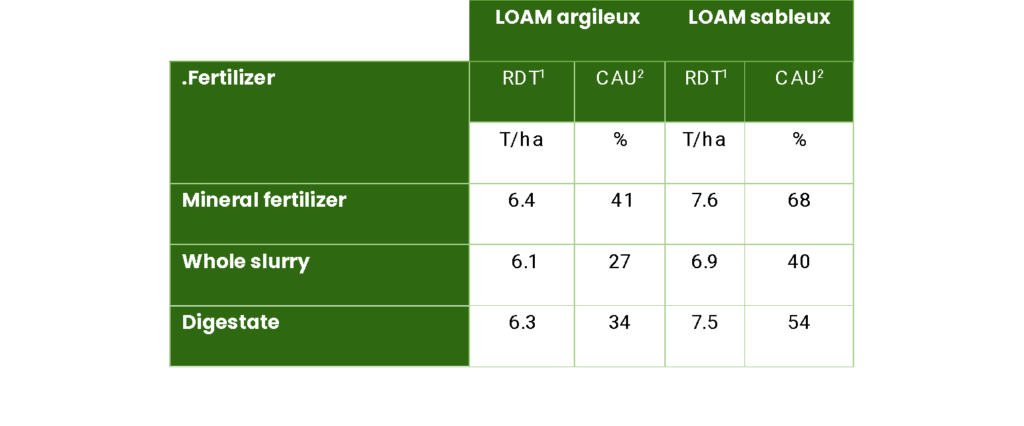

Here is a simulation comparing mineral fertilizers, whole slurry and digested slurry (digestate) adapted from the document Liquid by-products of slurry treatment, Porc Québec (2004).

1 Hay yield (RDT)

2 Apparent nitrogen utilization coefficients (CAU) LOAM is a textural class of soil composed of less than 52% sand, 28 to 50% silt (or silt) and 7 to 27% clay.

Comparison of digested slurry (digestate) to whole slurry

With a higher hay yield per hectare, digested slurry (digestate) also provides an apparent nitrogen utilization coefficient 7% higher than whole slurry in clay loam soil and 14% in sandy loam soil. The higher the CAU, the more the total nitrogen fraction incorporated by the mineral or organic fertilizer is absorbed by the plant until harvest.

When we evaluate the economic benefit of using digested slurry vs. whole slurry, this additional fodder per hectare represents:

1 Approximate hay price at $245/T (FAC, 2023)

2 Calculated for a herd of 50 lactating cows, 50 ha under cultivation fodder and 3 cuts.

In summary, the use of digestate compared to whole slurry in this study would provide savings of more than $50 per hectare per cut, as well as between $0.16 and $0.42 more per cow per day, not to mention the reduction in production costs. An increase in field yield is synonymous with a reduction in production costs, i.e.:

- Less equipment rental and transportation.

- Fewer greenhouse gas (GHG) emissions into the environment.

- More fodder reserves on the farm.

- Less use of the field and reduction of soil compaction.

- Better fodder quality, therefore increased production.

- More manure to return to the biomethanation process, therefore more royalty ($$/ton of effluent) and possibly more digestate to use as fertilizer in the field and less mineral fertilizer to use.

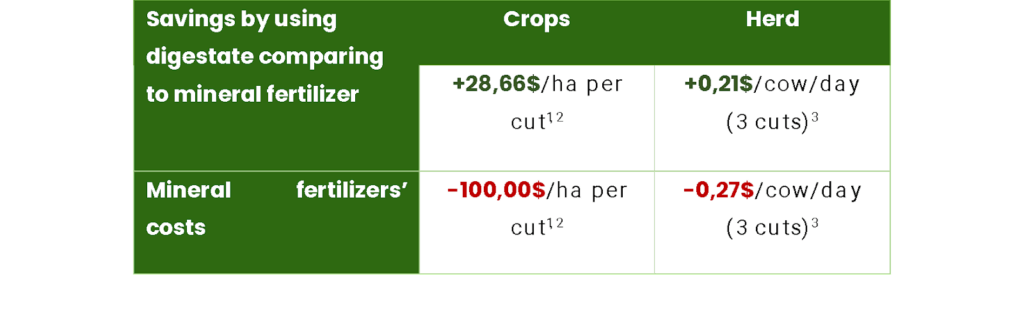

Comparison of digested slurry (digestate) to mineral fertilizers

Mineral fertilizers have demonstrated positive effects on the fertilization of agricultural soils over time, but we must consider the costs of these fertilizers, which are unfortunately very high. On the other hand, the digestate comes from a natural process which constitutes a good return on investment, since it does not generate as high costs as chemical fertilizers.

1 Price of a mineral fertilizer approximate to $1100/T (Producteurs de grains du Québec, 2023)

2 Calculated for a herd of 50 lactating cows, 50 ha in forage cultivation and 3 cuts.

Spreading the digestate

The digestate is brought back to the farm either in piles in the field at the location of your choice or returned to the pit. The product can be brought in whole or separated from its liquid fraction. Whole digestate is most often available (with a DM content of around 3 to 10%), but it can be separated into a liquid fraction (usually 1 to 6% DM) and a more fibrous fraction (usually 20 to 40%). % of DM).

Digestates with a higher DM content can be spread with most conventional manure spreaders, while whole and liquid digestates are best applied with precision application equipment such as a belt spreader, either a trailing hose or a trailing shoe, or shallow injector, to minimize ammonia emissions and maximize available nitrogen.

Points to bring home:

- The use of digestate has many agronomic benefits by improving soil health and field yields.

- Digestate is an interesting economic alternative because it reduces production costs associated with the use of mineral fertilizers.

- Royalties are paid to producers per tonne of manure/slurry supplied and transport is integrated into the activities of the biomethanation plant, which considerably reduces the costs of transporting livestock effluent to the farm.

- The digestate is stable and emits less odor than slurry or raw manure during spreading. In addition, the treatment of slurry and manure in closed digesters considerably reduces the dispersion of odors.

- The recovery of biogas during the biomethanation process will contribute to reducing overall GHGs.

- Clear improvement in the environmental record of farms using our services.

References

Chantigny, Martin & Angers, Denis & Rochette, Philippe & Bélanger, Gilles & Massé, Daniel. (2004). Les sous-produits liquides de traitement des lisiers. Porc Québec. https://www.agrireseau.net/porc/documents/Recherche-sous-produits.pdf

Czekala, Wojciech. (2022). Digestate as a source of nutrients: nitrogen and its fractions. Water. 14. 4067. doi.org/10.3390/w14244067

Financement Agricole Canada. (2023). Prix unitaire du foin 2023. https://www.fadq.qc.ca/salle-de-presse/actualites/2023/asrec-protection-foin-et-paturages-contribution-et-taux-de-prime-2023#:~:text=Prix%20unitaire%20foin%202023&text=236%20%24%20%C3%A0%20245%20%24%2Ftonne%20en%20r%C3%A9gie%20conventionnelle

Głowacka, Aleksandra & Szostak, Bogdan & Klebaniuk, Renata. (2020). Effect of Biogas Digestate and Mineral Fertilisation on the Soil Properties and Yield and Nutritional Value of Switchgrass Forage. Agronomy. 10. 490. doi: 10.3390/agronomy10040490.

Häfner, Franziska & Hartung, Jens & Kurt Möller. (2022). Digestate composition affecting N fertilizer value and C mineralization. Waste and Biomass Valorization. 13:3445–3462

doi.org/10.1007/s12649-022-01723-y

Koszel, Milan & Edmund Lorencowicz. (2015). Agricultural use of biogas digestate as a replacement fertilizers. Agriculture and Agricultural Science Procedia. 7. 119-124. doi: 10.1016/j.aaspro.2015.12.004

Pastorelli, Roberta & Valboa, Giuseppe & Lagomarsino, Alessandra & Fabiani, Arturo & Simoncini, Stefania & Zaghi, Massimo & Vignozzi, Nadia. (2021). Recycling Biogas Digestate from Energy Crops: Effects on Soil Properties and Crop Productivity. Applied Sciences. 11. 750. doi :10.3390/app11020750.

Producteurs de grains du Québec. (2023). Analyse du prix des engrais. https://www.pgq.ca/programmes-et-services/economie/prix-des-intrants/analyse-du-prix-des-engrais/